Canadian Cobot

Mike McLeod

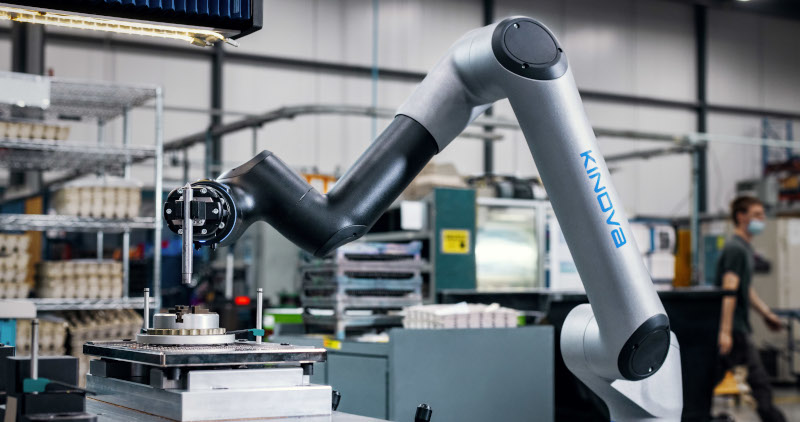

Automation General Machine BuildingMontreal’s Kinova Robotics leverages history of assistive robotics to develop its industrial Link 6 cobot.

While suited to typical cobot applications out of the box, Kinova’s Link 6 integrates a powerful controller with a local AI processing option designed to tackle highly complex applications.

(Photo credit: Kinova Robotics)

While Universal Robotics is credited with popularizing the technology and continues to hold roughly 50 percent of the global market, traditional robotics players (FANUC, ABB, etc) are catching up while other relative new comers jockey for position in this explosively lucrative industrial market.

One of the most recent industrial entrants is Quebec-based Kinova Robotics, which launched its Link 6 industrial cobot in March 2022. To classify Kinova as new to the overall industry, however, would be grossly misleading. Founders, CEO Charles Deguire and COO Louis-Joseph L’Écuyer, established the company in 2006 along with its first assistive cobot, the Jaco.

Inspired by a makeshift arm created by Deguire’s uncle, Jacques, who suffered from muscular dystrophy, the 6-axis Jaco mounts to and draws power from a wheel chair and can be controlled with a joystick, head control or most other assistive interfaces. Shortly after its launch, the Jaco was lauded for its ease-of-use, especially for an end-user base with little to no robotics experience.

Since then, the Quebec-based robotics firm has released three cobot models (Gen2, Gen3, Gen3 lite) for the assistive, research and medical markets, earning a number of accolades and inspiring investor confidence along the way.

Most recently, the company landed on Deloitte’s 2020 Technology Fast 500. It also raised C$40 million in February plus another C$20 million from the Canadian government under the Strategic Innovation Fund.

With ample financing in place, the company now looks to repeat its prior success in the crowded industrial cobot market. Analysts estimate there are more than 60 makers of cobots globally, collectively producing more than 200 individual models.

The question is how this Canadian cobot will stand out in the field. According to Jonathan Lussier, Kinova’s Director of Business Development, Integrated Solutions, the Link 6 market edge starts with where it’s produced.

“We are one of the only robot manufacturers left in North America,” Lussier says. “That represents a big opportunity for us in terms of short lead times and responsive support. The support aspect is really important and has been built up based on our experience working with our assistive customers. If they lose a robotic arm for a day it’s like chopping your own arm off for a day. So, it has always been critical for us to be very responsive in terms of those kinds of support requests.”

Beyond its geography, the Link 6 includes a number of hardware and software capabilities that make it unique. At first glance, the six-axis Link 6 cobot shares the characteristics that loosely define this robot category (e.g. light-weight, rounded segments, software limited movement speed, ease-of-use) and targets the sweet spot of the market.

With a maximum reach of 1 meter, the Link 6 can handle payloads up to 6kg and up to 9kg in applications where the payload or the end effector is closer to the base of the robot. In co-operative mode, the Link 6 maxes out at 250-500mm per second but can speed up to 1.65m per second with a repeatability of .03mm. These specs put it roughly in the range of Universal Robot’s popular UR5 and UR10 cobots.

The Link 6’s controller, however, is considerably brainier than most cobots, Lussier says. The controller’s compact, IP64-rated enclosure houses an Intel Core i7 processor, 8GB of DDR4 RAM and up to a 128 GB SSD running the company’s proprietary Kortex software platform.

“Compared to our main competitor, we have 10 times the processing power and four times the memory,” Lussier says. “That’s a big differentiator when you’re talking about more advanced applications.”

The advantage, he adds, is that the Link 6 controller can handle tasks that would normally require additional external controllers to coordinate vision systems for inspection or quality checks or to deal with the complex end-effector tooling.

And, in addition to its normal processing power, the Link 6 is also the first cobot with the option to incorporate a GPU to add AI capabilities, which opens up use-cases not typically associated with cobots.

“High speed is a funny word to use with a cobot but, if you look at traditional high-speed, vision-guided pick-and-place where the products are variable, the vision component is huge in terms of the cycle time,” he says. “By integrating AI-based applications directly in the robot, you can reduce cycle time quite a bit, such that a cobot with a more advanced vision system can be faster than a traditional robot with a traditional vision system.”

Moving up the arm, Lussier points out that the Link 6 is the first cobot with a dedicated gigabit line throughout the system, which allows for the integration of GigE vision cameras without requiring external wiring. The arm also delivers six to eight times more electrical power which enables advanced end-effectors and sensing systems.

The Link 6’s “wrist” incorporates this UL-certified enabling device that

enhances user safety and enables a streamlined “teaching mode” programming method.

(Photo credit: Kinova Robotics)

“The interaction between the buttons on the wrist and our visual programming is extremely tight,” Lussier explains. “Basically, you can simply start clicking buttons on the wrist – to take waypoints, open and close the gripper and speed up or slow down the arm – and our programming interface will automatically create a visual program on the connected tablet or computer.”

From there, he adds, users can refine the operation via high-level, low-code block programming or delve deeper into the code via Python and eventually C++.

For its initial release, Lussier says the Link 6 is setup to handle standard cobot applications, including CNC machine tending and pick-and-place. However, due to its high level processing capabilities and AI expandability, its the future applications that may not have been thought of yet, that Kinova foresees its Link 6’s strengths coming to the fore.

“We are lucky to have our robots and 500 different institutions around the world, so we are very aware of what’s going on in the market in terms of the research, which is 5 or 10 years ahead of the industry,” Lussier says. “With the Link 6, we built a robot that was best adapted to those future applications.”

www.kinovarobotics.com